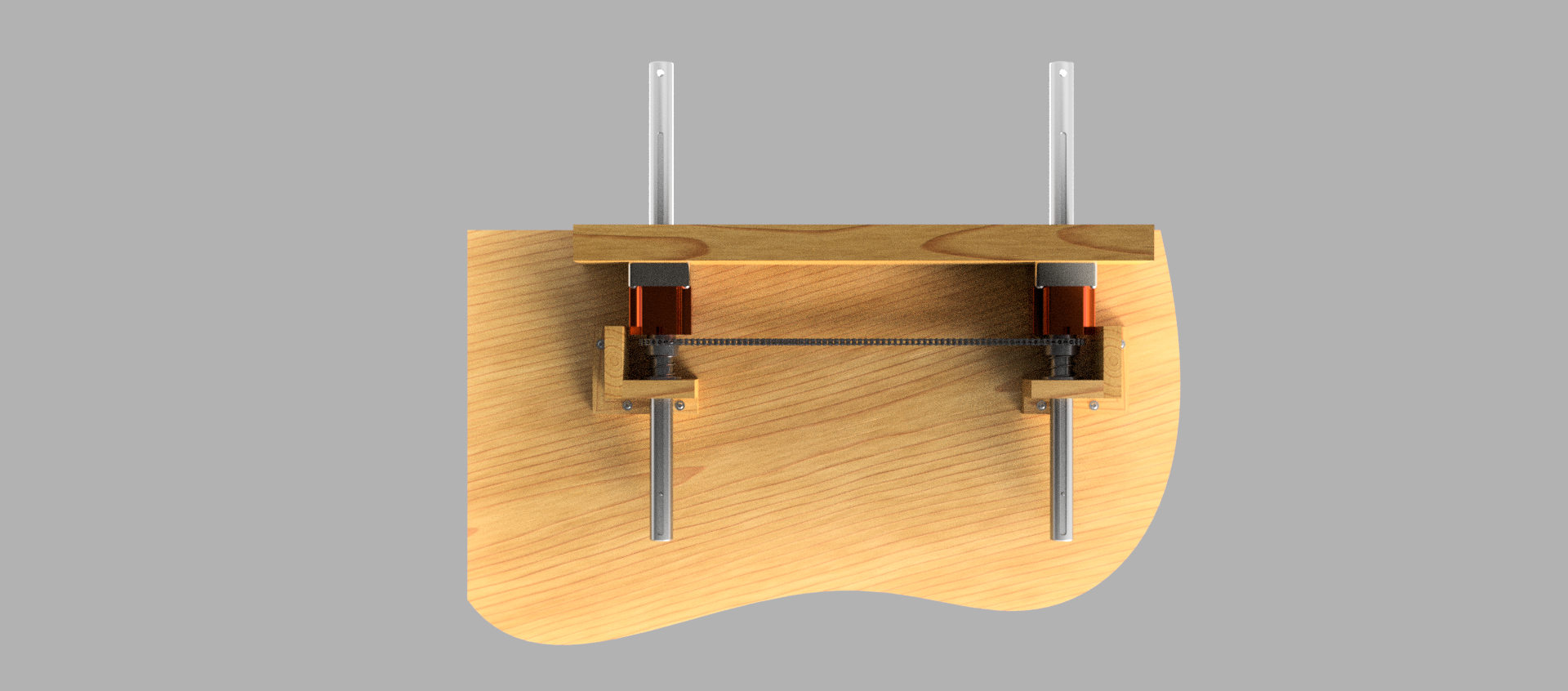

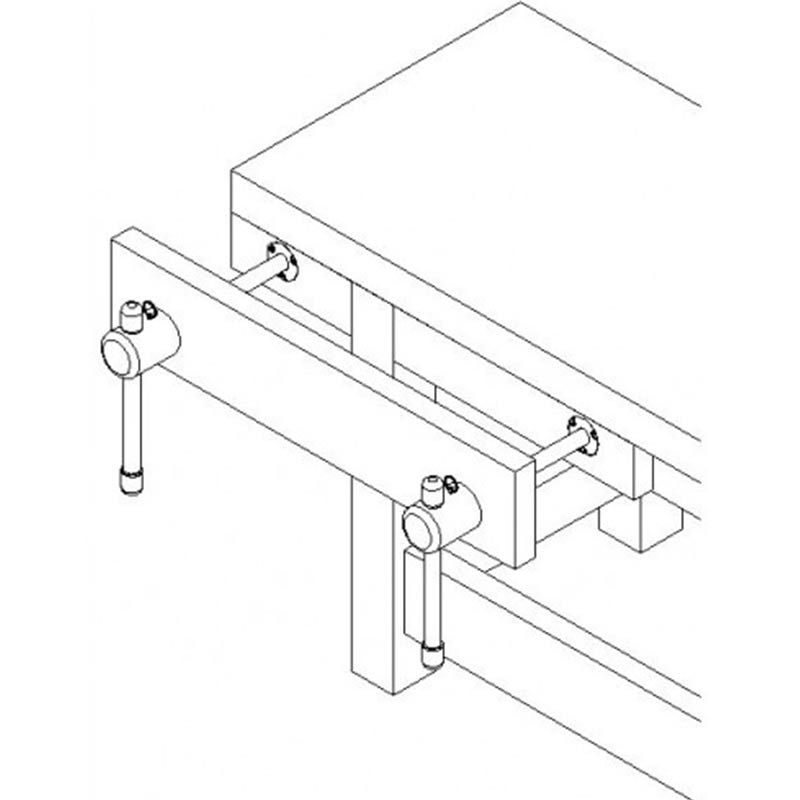

Traditional twin screw vises excel at clamping wide work upright between the screws without racking. Unfortunately, each screw needs to be turned independently to clamp the work. By connecting vise screws together with a chain only one screw needs to be turned and clamping can be attained without racking. Unfortunately, you still have to do a lot of cranking for gross adjustments. The VX21 Face Vise can solve this.

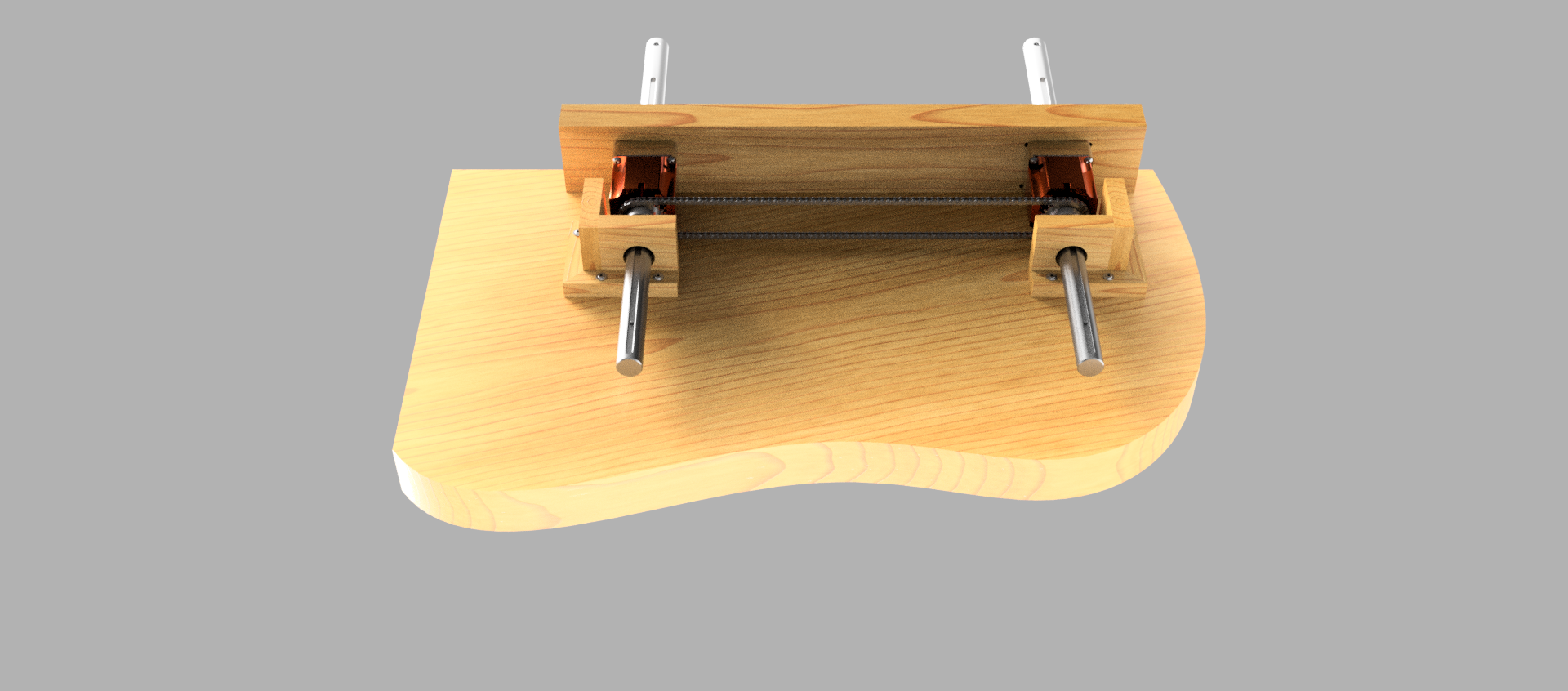

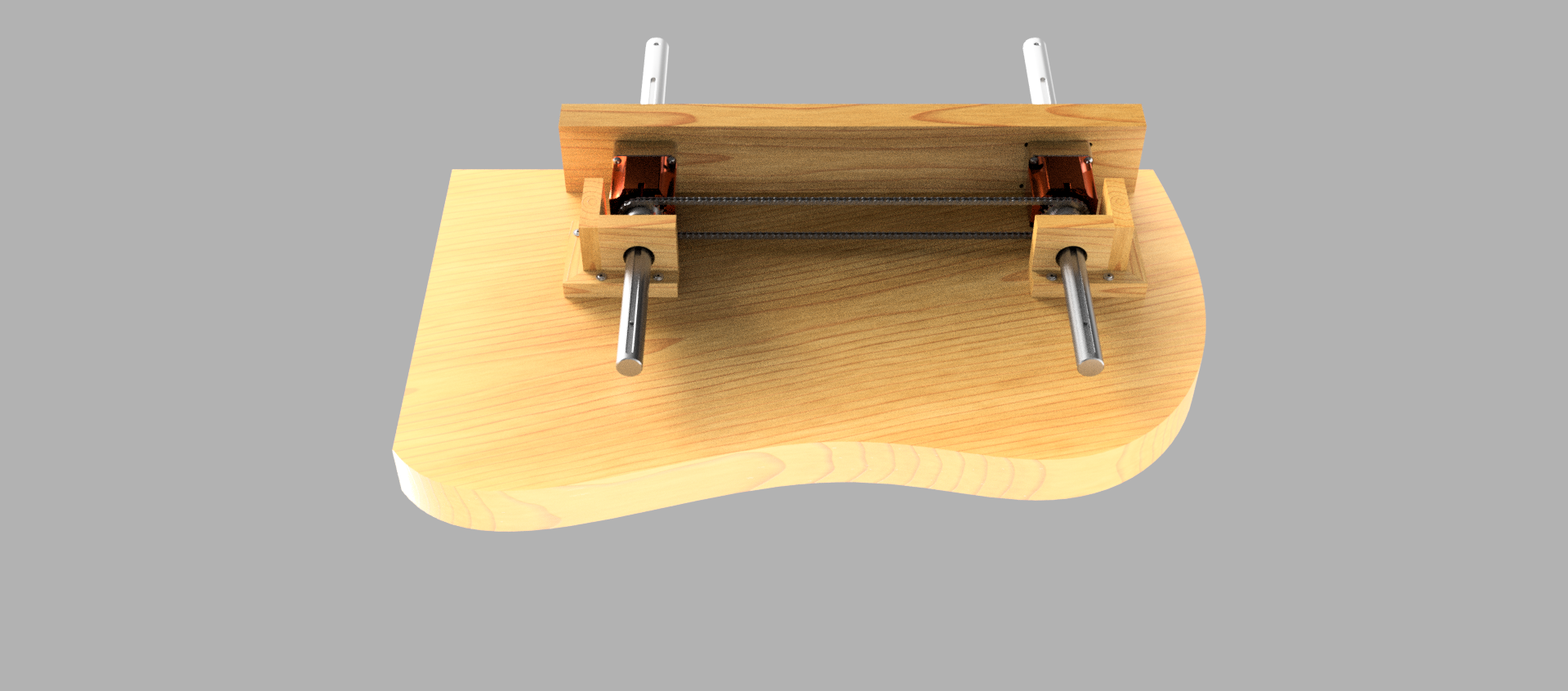

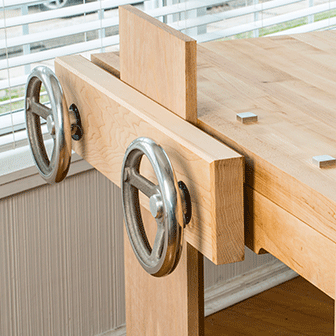

TheVX21 face vise has a very quick action and clamps firmly with very little turning of the clamp handle. It is the only quick action twin shaft vise on the market and the unique design operates without screws. The vise has the appearance of a traditional wooden twin screw vise but will allow you to spend less time cranking a vise in and out. It is customizable to meet your needs. The clamp shaft to clamp shaft spacing can be made up to 25” in ¼” increments, allowing the vise to replace an existing vise or to be used at the end of the bench as an end vise (the maximum stock width that will fit between the clamp shafts is 1 inch less than the clamp shaft center spacing). The VX21 face vise is sold as a hardware kit, the handles and other options are sold separately. We offer your choice of metal hand wheel or wooden hub and handle, both come with a quick release pin to allow you to quickly remove your vise jaw if desired. You may also construct your own handles. You may also configure the VX21 face vise as a single handle vise if desired. Simply order your choice of hand wheel or wooden hub and order the single handle cap. The single handle option is a good choice for narrower vises where the two handles could interfere with each other or if you just prefer a single handle.

Face Vise Advantages:

- Quick release and engage. Simply slide the jaw against your work and turn either clamp handle.

- No racking or sagging – operates without lubrication on the clamp shafts – your work stays clean.

- Traditional appearance with smooth precise action. Available in single or twin handle configuration.

- Clamp shaft center distances up to 25” in ¼” increments.

The VX21 Face Vise hardware kit includes:

- 2 – Fully assembled VX21 face vise hardware assemblies with hardened steel clamp shafts.

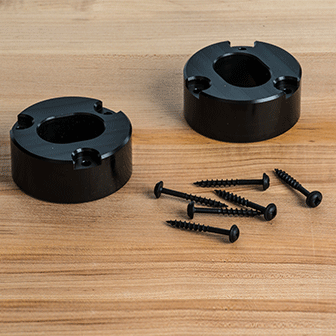

- 2 – Black Delrin bearings.

- 2 – Shaft collars.

- Mounting hardware.

- Comprehensive instructions via PDF download from the instructions page.

Ordered Separately:

- Metal hand wheel.

- Wooden hub and handle.

- Single handle cap.

- Slotted bearing for front jaw.

Patent Pending. Please allow up to 4 weeks for delivery. Vise jaws not included. Shipping weight 18 pounds.

Keith Bellamy –

I purchased the VX20F face vise in March of 2016 and installed it on my 21st Century Workbench (R. Lang). The VX20F vise mechanisms are delivered assembled with the clamp shafts installed. Installation onto my WB involved some layout, drilling & mounting the clamp assemblies. The instructions provided were thorough & accurate. I added some strips of thin cork to my vise chop for added grip. I installed the VX20F 25″ O/C & have 9.5″ of open capacity. The ability to quick-release this vise is key for me.

Keith Bellamy –

I purchased the VX20F face vise in March of 2016 and installed it on my 21st Century Workbench (R. Lang). The VX20F vise mechanisms are delivered assembled with the clamp shafts installed. Installation onto my WB involved some layout, drilling & mounting the clamp assemblies. The instructions provided were thorough & accurate. I added some strips of thin cork to my vise chop for added grip. I installed the VX20F 25″ O/C & have 9.5″ of open capacity. The ability to quick-release this vise is key for me.