Description

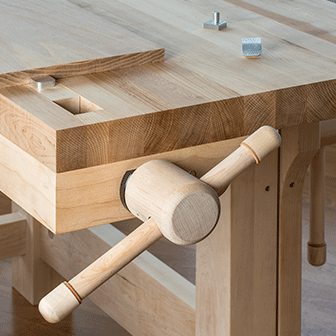

The VX21 wagon vise is the only quick action wagon vise on the market! Now with the same great improvements as the leg vise mechanism. A traditional screw operated wagon vise is a compromise between quick movement of the vise jaw and mechanical advantage. The tradeoff is the use of a 2 tooth per inch (TPI) screw to give a reasonable rate of travel and then have a lot of really closely spaced dog holes to compensate. Your bench top looks like Swiss cheese and requires a lot of extra work to make.

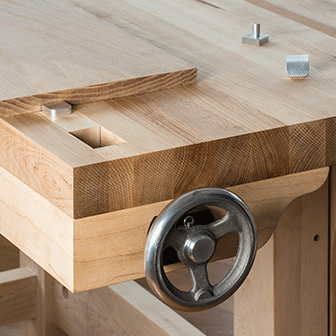

The New Hovarter Custom Vise VX21 wagon vise gives you quick action (as quick as you can slide the dog block against your workpiece) and then simply turn the handle and start clamping with high mechanical advantage. Three times higher mechanical advantage than a 2 TPI screw. You get quick action and a lot less force input is required from you for clamping. A typical screw operated wagon vise with 12 inches of travel would require 24 complete revolutions of the handle to traverse the 12 inches. That’s a lot of wasted motion. With a typical screw operated wagon vise the dog holes would be spaced about 4 inches apart. You need at least a dozen dog holes in the bench top. The VX21 wagon vise has 11-1/4” of travel and the dog holes can be placed 10-1/2” apart!

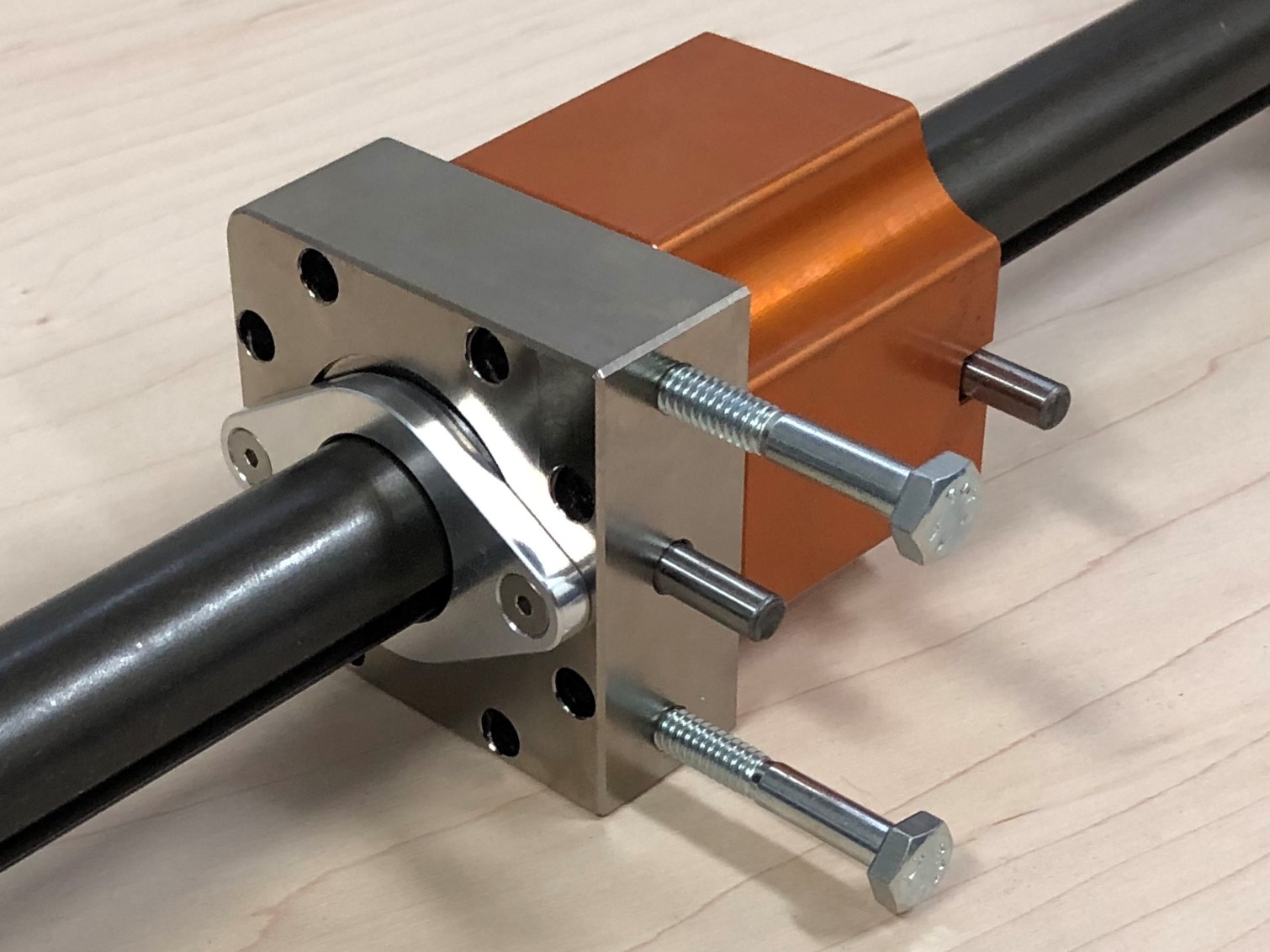

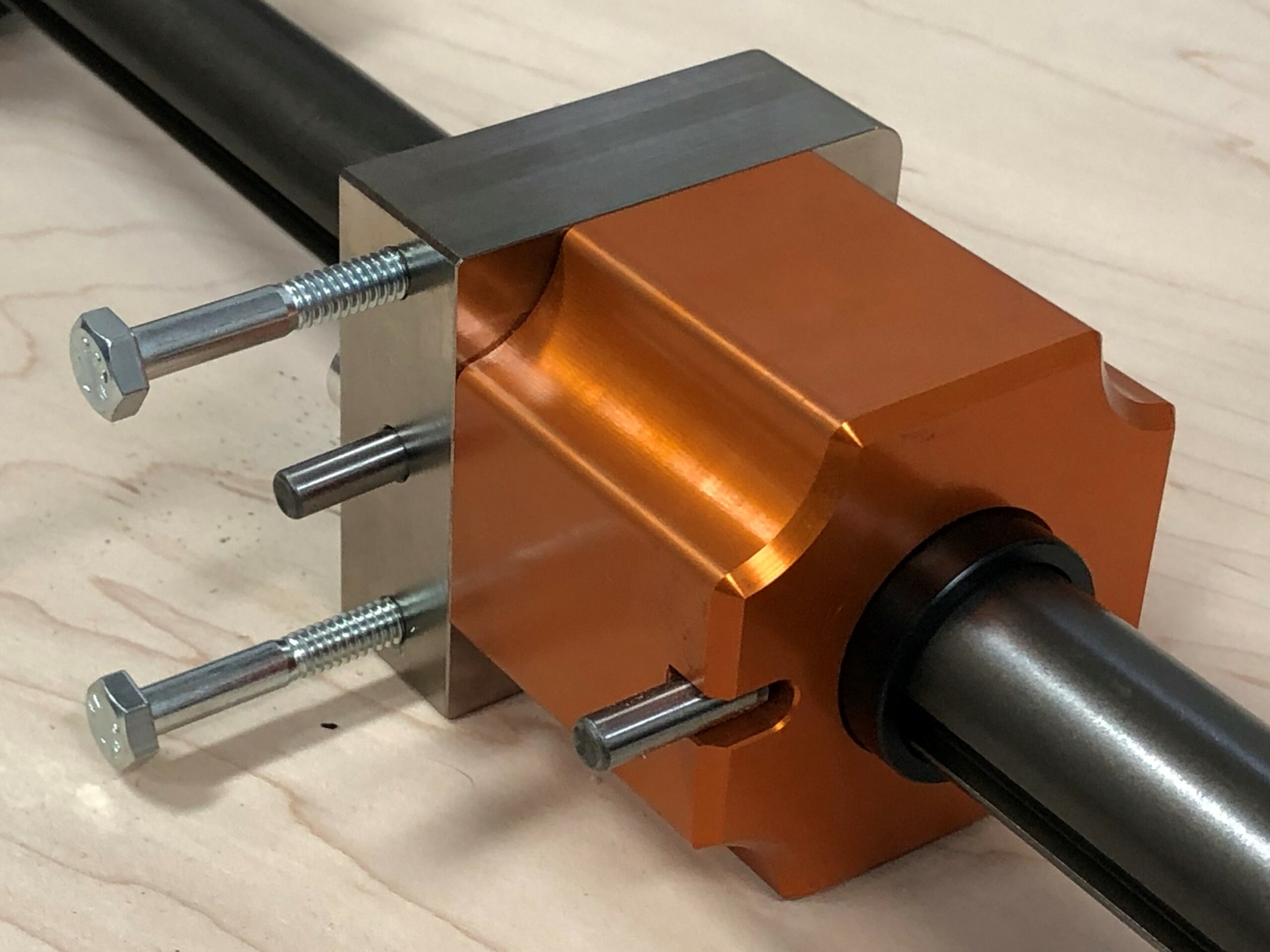

The VX21 wagon vise is a lot smaller than our previous wagon vise design. It has been reduced in size by 23%. It requires a lot less material removal if your installation requires a cavity in a thick bench top. The VX21 wagon vise also has a new innovative dog block mounting system. It utilizes a bolt and pin system for mounting the dog block to the vise mechanism. Only two bolts are required to secure the dog block to the mechanism while 2 steel pins locate and secure the dog block. This gives you ease of assembly while creating an incredibly rigid dog block mount.

For ease of assembly the clamp shaft is removable. To install the vise simply slide the clamp shaft in from the end cap end and through the vise mechanism and into the rear bearing. A key retainer and key is installed with 2 screws into the mechanism.

Over 4 years in development and testing, the VX21 wagon vise is engineered to be the best! Check out these outstanding features:

VX21 Wagon Vise Features

Increased mechanical advantage:

Three times more mechanical advantage vs. 2 tooth per inch screw typical of most other vises. This equates to much greater clamping force with less applied force to the clamp handle. This is great for use with a small metal handwheel because it affords less leverage than a long clamp handle. Additional design changes have decreased friction in the mechanism – also increasing mechanical advantage.

Increased clamping force:

The new VX21 vise mechanism has been tested with a force gauge and can easily apply over 1100 pounds of force!

Increased clamp travel:

A quick action vise gives you the best of both worlds by allowing you to quickly position the jaw against the workpiece and then easily apply a high clamping force. Typically, only a small amount of clamp travel is needed but the VX21 wagon vise has an 88% increase in clamp travel over the previous wagon vise mechanism. Total clamp travel of the VX21 wagon vise is 3/8”. You’ll never run out of clamp travel.

Decreased package size:

23% decrease in package size with symmetrical design. Allows the mechanism to easily fit into tighter areas. The footprint of the VX21 wagon vise is 2-5/8” X 2-5/8”.

Easier assembly:

Clamp shaft is easily removed without dis-assembly of the mechanism yet is retained when the key retainer is attached. This makes assembly a breeze if you have a very thick end cap.

Ruggedized design:

The VX21 wagon vise has a 66% increase in weight versus the old wagon vise while decreasing package size 23%. The increase in weight is due to the increased use of steel and the massive one-piece aircraft grade aluminum anodized housing.

Steel base is electroless nickel plated (ENP) to prevent corrosion and creates a low friction, hard, wear-resistant surface. It also has a stunning appearance.

The mating internal part of the steel base utilizes a steel alloy with low friction properties and natural lubricity.

The aluminum housing is secured to the mounting base with 8 high strength steel socket head cap screws making an incredibly stiff and durable assembly.

New robust clutch system has been painstakingly tested through thousands of clamping cycles and is designed to last a lifetime.

The dog block mounting system utilizes two 1/4-20 bolts threaded into the steel base through clearance holes. The dog block is kept in position by two pins. One pin fits in a close-fitting hole in the steel base and the other pin fits in a close-fitting slot in the housing. The slot allows you a little more tolerance when you drill the pin holes in the dog block but the precision steel pins fit tightly in the hole and slot of the mechanism. The fit of the pins into the mechanism is just a few thousandths of an inch. We build the tight tolerances into our mechanism and allow you to drill holes with ±1/16” position tolerance and still have an incredibly rigid assembly!

Precision tolerances throughout:

Tight internal tolerances and accurate alignment through the use of precision steel dowel pins create a mechanism with silky smooth lockup and clamping. The accurate alignment creates low clamp shaft drag and very consistent performance.

No lube on clamp shaft:

Just like the old wagon, there is no need to grease or oil the clamp shaft. This keeps your work clean and does not attract dust and dirt.

Patent pending:

All of the various design improvements listed above have necessitated the need for a new patent filing. We believe this is the absolute finest and most robust vise mechanism on the market today!

Instructions:

Reviews

There are no reviews yet.